Waterproof paint Polyurethane (1C)

€94.87

Tax included

POLYURETHANE WATERPROOF PAINT LIQUID (1 - component)

POLYURETHANE WATERPROOF for waterproofing and coating in the following situations:

- Roofs, terraces, balconies and roofs.

- Metal Roofing, fiber cement.

- Swimming pools, ponds.

- To protect the polyurethane foam.

MEND LEAKS AND LEAKS. TRAFFICABLE And ELASTICO

Al comprar este producto, acumulará 20 puntos con nuestro programa de fidelización. Puede convertir 20 puntos en su cuenta en un cupón para una compra futura.

Al comprar este producto, acumulará 20 puntos con nuestro programa de fidelización. Puede convertir 20 puntos en su cuenta en un cupón para una compra futura.

Buy paint 1 - component polyurethane waterproofing for pools, decks, terraces, balconies etc ...

.

BUY POLYURETHANE WATERPROOF A COMPONENT

.

NATURE OF PAINTING WATERPROOFING POLYURETHANE MONO COMPONENT

It is a liquid product-component based on a pure polyurethane elastomer once catalyzed humidity forms a continuous and elastic membrane without joints or overlaps, without reinforcing mesh surface (except Catalan tiles) whose authorize properties and optimum sealing waterproofing in plurality of supports. TRAFFICABLE AND STRETCH

TECHNICAL DATA POLYURETHANE WATERPROOFING 1C

Density: 1.32 to 1.42 g / cm3 (slight variations depending on the color)

|

23C viscosity: 2650 cp Dry extract weight at 105 ° C:> 90% |

5-6 hours. 2-3 hours

5-48 hours 3-24 hours

|

|

|

Flash point: Ashes at 450 ° C: Application temperature: Shore A hardness at 23 ° C: Tensile strength: Drying time:

Reaction to fire: Recoat:

|

42 42-47% 5-35ºC > 75 5-6 MPa Without accelerant: With accelerant: Euroclass E without accelerant: with accelerant: |

|

|

Elasticity (elongation) at 23C: 418%

|

||

Resistance to water vapor transmission: μ = 2500

Permeability to water vapor transmission: 14 g (m 2 / day)

Adhesion to concrete at 23 ° C:> 2MPa

.

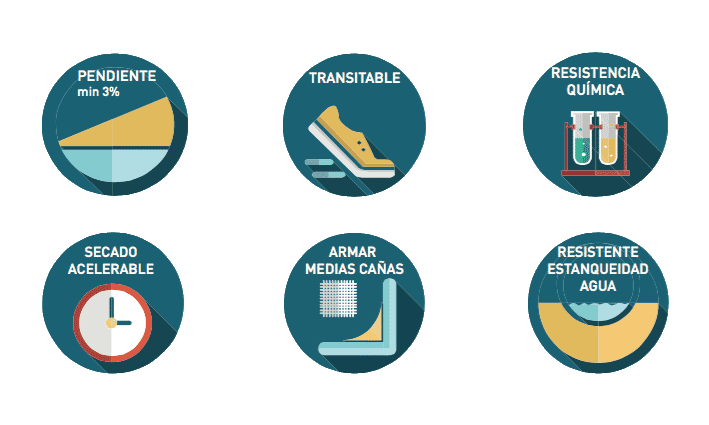

FEATURES waterproof paint one - component polyurethane

- It is a membrane of high elasticity and wear resistance that applied once offers great stability and durability.

- Fits on any surface even on uneven areas (curved or square).

- Reinforced surface is not necessary only in singular points with other building elements, records water (sinks), sharp edges, corners, coving, ...

- It can be applied in one single layer 1.5 mm thick by mixing it with accelerant which increases execution speed by reducing labor costs application. Do not use projection equipment in this type of application accelerant or use this

additive when the temperature is above 20 ° C.

- With the application of this product save together and any joint type and the finish is uniform.

- The application should not be made with moisture or water support either at the time of application as a posteriori (capillary pressure water table).

- Being an aromatic membrane yellowing when subjected to UV but maintains its mechanical properties and chemical resistance. To avoid this effect can be protected with 2-component aliphatic polyurethane S12 color to be determined.

- The adhesion of the product is very good on any surface such as concrete, mortar, metal, polyurethane foam although the application is recomieda (I25) Water epoxy primer to avoid bubbles in the membrane surface.

- Due to its mechanical strength properties is passable, can give you a rough finish slip if the system ends with a (S12) Polyurethane floors slip resistant.

- Supports temperatures at 80 -40ªC retaining elastic properties.

- You can put ceramic flooring on top. In this case it is desirable to sprinkle dry silica improve anchoring in the last layer of the product.

- For applications in veritcal walls, it is recommended to use 1 liter of anti-sagging Thixotropic Membrane, to prevent the product from sagging when applied.

.

Advantages

- No need mixing, is easy to apply and is ready for use

- It moves with the movement térmicos- maintains its flexibility even at low temperatures

- Weatherproof almost immediately after application

- Economic - provides an effi cient solution to increase the shelf life of damaged roofs

- It does not require heat or flame

- Easily be repainted if necessary-does not require disposal

-

- Special for trafficable areas.

- Resistant to sun without losing properties although some color over the years.

- elastic material that adapts to weather conditions.

- One component.

- Made solvent based

.

WHERE CAN I APPLY WATERPROOFING polyurethane paint?

Polyurethane membrane for waterproofing and coating in the following situations:

- Roofs, terraces, balconies and roofs.

- Metal Roofing, fiber cement.

- Swimming pools, ponds.

- To protect the polyurethane foam.

.

HOW SHOULD APPLY PAINT POLYURETHANE WATERPRROF (1 - component)

In general it should be consideration the following factors prior to the application:

- Repair surfaces (filling voids, lasirregularidades removal, removal of old impermeabilizacionesexistentes ...)

- Clean the support eliminating dust, dirt, grease existing oeflorescencias.

The supports on which can be applied polyurethane membrane are multiple and according to their nature or state will proceed differently, taking into account the singular points listed in the Annex to application.

Next we will detail different types of support:

CONCRETE

Existing voids or areas in poor condition must be repaired with suitable cement mortar or epoxy resin mortar (Mix I18 Epoxi Primer HIGH THICKNESS water 1 part with 4 quartz aggregate).

It must be fully cured (mímimo 28 days), cement slurries must be eliminated getting through mechanical treatment (shot blasting, diamond, milling), an open-pore surface.

Subsequently clean and remove all surface contaminants or dust from mechanical treatment.

Apply the I25 Priming Epxi water under the conditions and parameters indicated in the data sheet.

METALLIC SUPPORT

Metal surfaces should be prepared by blasting to improve the anchorage. Sometimes it will be necessary to apply corrosion inhibitor.

Review joints, and seams where you have to perform actions with polyurethane caulk or adhesive geotextile band in combination.

For fast and effective cleaning of the surface using cleaning solvents.

Apply a pre anticorrosive primer epoxy or polyurethane type to improve the adhesion and chemical resistance.

ceramic support

Ceramic surfaces in joints should be filled with polyurethane caulk and if necessary supplemented with geotextile adhesive bands.

For quick and effective cleaning of the surface using pressurized water and check its total evaporation. If no porosity is advisable mechanical treatment.

Then apply the I25 Epoxy Primer water. The checking primer drying is performed to the touch, the time ranges from 4 to 10 hours depending on the temperature.

The primer loses its properties recoatability with polyurethane to 24 hours of application.

The polyurethane waterproofing can be applied by spraying machine-less air at a pressure of 280 bar or manually by brush, roller or rubber rake. In these cases it must be done uniformly.

In low temperature environmental conditions using polyurethane accelerator (never to temperatures above 20ºC). In this case you can be applied 2 kg / m2 material in one hand.

If you apply 2-3 coats in the interval between layers it is 5-48 hours and 3-24 hours accelerant.

After the application of the polyurethane membrane before after 48 hours (24 hours with accelerant) it is necessary to protect from UV rays, when color stability is requested, with the product (S12) Aliphatic polyurethane flooring two components in color can be set non-slip finish.

.

PRECAUTIONS WHEN USING POLYURETHANE WATERPROOF PAINT

No special precautions regarding toxicity. It is not flammable.

IMPORTANT: If oxygen enters the bottle (it is opened before use) the product dries due to ambient humidity, which is why it is catalyzed. The product should only be opened at the time of use. Returns of this product will not be accepted if signs of having opened it are intuited.

PRESENTATION OF PAINTING WATERPROOFING POLIURETAN

It is available in packs of 5 and 25 kilos.

ANNEX USSE OF PAINT WATERPROOF 1 - component (R11)

Singular points to consider:

Sometimes it is necessary to perform preliminary work acondicionamientoantes applying the system because it relies heavily on the waterproofing is fully effective and lasting.

We detail the most common elements that we can find, if you encounter undescribed elements and doubt contact our Technical Department.

MEETING OF PIPES

In the rehabilitation work, once the pan ready to proceed to place a frame that exceeds about 10 cm diameter downpipe, subsequently impregnate with polyurethane waterproofing to attach it to the support.

EXPANSION JOINTS

Fill the joint with polyurethane putty and then apply a band of adhesive geotextile. This should cover between 10-15 cm on each side of the board.

Fissures and cracks

passive and active cracks of more than 3 mm wide. After opening with disc seal it with polyurethane caulk or with the same waterproofing (must be elastic material).

EDGES ALIVE

Sharp edges should be rounded and angulated very adhering points if a band geotextile necessary to arm.

CABELADO / RAISINS WALLS

cables and feedthroughs of the decks as unique elements and must be treated before waterproofing work are considered.

MEETINGS WITH VERTICAL PARAMETERS

a small pedestal minimum height of 10 cm (reed) meets with the flat sealing is performed.

the corner with a polyurethane putty subsequently a band adheres geotextile and applied over the first polyurethane waterproofing seals.

.

.

We guarantee the quality of our products in accordance with our General Terms and Conditions of Sale and Delivery.

Our advice on application technologies, whether verbal, written or through testing, is based on our current level of knowledge and experience. These are simple instructions that do not affect our responsibility and do not exempt you from the need to check for yourself whether the products we supply comply with the procedures and objectives you seek, carrying out your own controls and tests. The application and use of the products is beyond our control and is therefore solely your personal responsibility. We cannot be held responsible for results other than those presented here. Our security recommendations do not prevent you from defining your own measures, adapted to the conditions of your systems. We reserve the right to change the data contained herein without prior notice based on technological advances.

- Repainted

- 5 - 48 horas

- Theoretical performance

- 2 kg / m 2 (1.7 mm thick)

- FINISH

- Glossed

- Solvent

- Disolvente Industrial de Secado Rápido

- Useful of Application

- BRUSH / ROLLER / AIRLESS

- Cleanliness Tool

- Industrial Dried Rapid Solvent

- Time of dried to a temperature of 25 ºC and a relative dampness of 50 %

- 5 - 6 horas

- Temperature of Application

- Between 5 and 35 centigrade degrees

- Density

- 1.32 - 1.42 grs/cm3

- Adherence to the support

- Mayor 2MPa

- Humedad del soporte

- Inferior al 10 %

R11

993 Items

Customers who bought this product also bought:

Reviews (8)

Reviews (8)

Impermeabilizante

Puntuación total:

Muchas gracias por la atención, el producto muy buena calidad y completa su función impermeabilizante para la terraza.

Le pongo 5 estrellas, 4 por el producto y una más por la atención al cliente y las explicaciones

Impermeabilizar piscina

Puntuación total:

Queria un buen producto para impermeabilizar mi piscina y este cumplió todos los requisitos es muy bueno y me ha quedado de maravilla, además la atención al cliente de esta tienda es muy buena y me ayudo mucho con mis dudas

impermeabilizador

Puntuación total:

Lo utilice en mi terraza y un gran resultado, tambien muy buena atencion al cliente y he comprado mas productos en esta tienda y tanto este como los demas tienen una exceelente calidad